Nordberg® HP300™ cone crusher - Metso

Nordberg® HP300™ cone crusher is a medium-sized model in the renown Nordberg® HP Series™ cone crushers family. It is an efficient crusher

consulter en ligne

Nordberg® MP1000™ cone crusher - Metso

Nordberg® MP1000 cone crusher brings the highest capacity cone crusher to bring benefits to any operation. High availability. This cone crusher provides more availability

consulter en ligne

Cone Crusher - an overview ScienceDirect Topics

Cone Crusher. Cone crushers give the best results when operating in closed circuit with screens. From: The Science and Technology of Cement and Other Hydraulic Binders,

consulter en ligne

A review of modeling and control strategies for cone crushers in

the aggregates and mineral processing industries, run-of-mine ore is broken in crushing circuits by cone crushers. Here, we review the cone crusher literature, focusing on the

consulter en ligne

Nordberg® GP Series™ cone crushers - Metso

Features. Nordberg® GP Series™ cone crushers have been developed to crush feed materials into desired end products efficiently, reliably, and economically. Engineered for all rock types, these machines can be

consulter en ligne

Greatest application fit Nordberg® GP Series™ cone crushers

Nordberg GP Series cone crushers are widely and globally utilized in aggregates production and mining operations. The excellent performance-to-footprint ratio and unique cup

consulter en ligne

A review of modeling and control strategies for cone crushers in

2021.8.15 open access • We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of

consulter en ligne

Prediction of power consumption and product size in cone crushing

1991.1.1 This paper presents the measurement and analysis of energy consumption of a laboratory jaw crusher during concrete recycling. A method was developed to

consulter en ligne

Chamber Optimization for Comprehensive

2021.3.15 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of

consulter en ligne

Most Common Issues With Cone Crushers Mellott

2023.4.24 Excessive Vibration of the Cone Crusher. If your cone crusher is vibrating far more than it should, you might have loose fastening bolts in the base, broken or worn parts, or poor lubrication. Alternatively,

consulter en ligne

Types of Crushers: What You Need to Know - Machinery Partner

Cross section of a Kleeman primary jaw crusher Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

consulter en ligne

McLanahan CMB Cone Crushers

The controls of the CMB Cone Crushers comprise a contactless in-cylinder transducer and an operating console that can be positioned close to the crusher. Quick release, self-sealing couplings are used to connect the twin hydraulic hoses that run between the crusher and console. The console houses the fluid tank, motorized hydraulic pump, valves ...

consulter en ligne

Gyratory and Cone Crusher - ScienceDirect

2016.1.1 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°.

consulter en ligne

A review of modeling and control strategies for cone crushers

2021.8.15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

consulter en ligne

Crusher - an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 8.2). Power is transmitted from the source to the countershaft to a V-belt or direct drive.

consulter en ligne

Crushing Products Size and Shape -What to Expect - 911

2016.2.26 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product. If our problem had covered a crushing condition calling for 80 instead of 85% passing the

consulter en ligne

Greatest application fit Nordberg® GP Series™ cone crushers

any other cone crusher with an equal head diameter. Despite the excellent performance, GP Versatiles are quite compact crushers, highlighted by the cup piston design which saves space underneath the GP crusher. Excellent power-to-footprint ratio requires smaller steel structure investments, making crusher replacements much more straightforward.

consulter en ligne

Crusher - Wikipedia

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones. A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear-resistant mantle, and the enclosing concave hopper, covered by a

consulter en ligne

A review of modeling and control strategies for cone crushers in

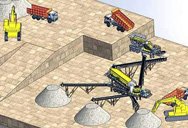

the aggregates and mineral processing industries, run-of-mine ore is broken in crushing circuits by cone crushers. Here, we review the cone crusher literature, focusing on the modeling and control of crushing circuits. A total of 61 works published in the primary literature, ranging from 1972 to 2020, are classified and discussed with

consulter en ligne

Development of wear model for cone crushers - ScienceDirect

2006.8.30 Run-of-mine ore is usually too large to be useful for construction or metallurgy. Large particles must be reduced to specific sizes to either comply with aggregate sizing regulations, or facilitate mineral liberation; therefore, in the aggregates and mineral processing industries, run-of-mine ore is broken in crushing circuits by cone crushers.

consulter en ligne

Calibration and Validation of a Cone Crusher Model

2021.11.11 This paper reports the calibration and validation of a cone crusher model using industrial data. Usually, there are three calibration parameters in the condensed breakage function; by contrast,

consulter en ligne

SANDVIK QS332

2021.4.7 CS430 cone crusher, it is capable of handling a feed size up to 90% larger than standard cones. It is able to produce large reduction ratios with minimal fines production and is ideally suited for crusher run, ballast, drainage stone or material for a tertiary crushing plant. The QS332 is available with a choice of three crushing

consulter en ligne

Prediction of power consumption and product size in cone

1991.1.1 To better understand and predict power consumption during the crushing stage and the product particle size distribution as a function of the CSS, feed size and rock strength, Bearman et al. (1991) performed pilot-plant scale experiments using a laboratory scale cone crusher. The authors drew some conclusions regarding the relationship

consulter en ligne

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

consulter en ligne

Cone Crusher Troubleshooting Guide: Common Issues and

2023.2.24 By following these guidelines for optimal feeding conditions, you can help ensure the longevity and efficiency of your cone crusher, ultimately saving you time and money in the long run. Check Discharge Area for Adequacy. Another important factor to consider when troubleshooting a cone crusher is checking the discharge area for

consulter en ligne

5 tips for energy efficient and productive cone crushing - Metso

2020.4.15 Cone crusher hydraulic power unit maintenance; Improper hydraulic power unit maintenance can cause the pump and motor assembly to cycle more often than it should or worst-case scenario, to run continuously throughout the day. This inefficient use of connected horsepower will result in a higher energy cost per ton of material crushed

consulter en ligne

Jaw and Cone Crusher Myths Total Operating Costs - RUBBLE

If your application permits to use an impact crusher over a jaw and cone crusher setup there are numerous reasons that support the use of an impact crusher. Less fuel burn: Only one machine burns fuel. For example, if you can save 8 gal / h in fuel over 1,500 hours a year at an average fuel cost of $4.50 per gallon this equates.

consulter en ligne

Portable Plants CRC1150 Cone Plant - Terex

The Cedarapids® CRC1150 cone plant delivers big production at an affordable price. The highly mobile plant features the TC1150 cone crusher that utilizes high efficiency roller bearings and boasts several notable advancements that enhance performance and functionality. Key features include automated cone controls and larger closed side settings.

consulter en ligne

The pros and cons of cone crusher applications - Quarry

2021.4.16 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. ... In general, a coarse crusher, such as a secondary cone in open circuit, should be run at the low end of the speed range. As

consulter en ligne

- vues de detail du broyeur

- pierre machine de concasseur palnt karntaka

- technologie de lavage de minerai de bauxite en amérique

- Broyeur de fonctionner à la place de la chaux

- meules flûte concasseur à mâchoires soins de

- cout de 200 tph usine sbm de concassage 3 etapes

- concasseurs à cone classique

- costo del molino de bolas de cemento

- uso del yeso mineral

- concasseurs portables pour pierres précieuses

- entreprise de traitement des minéraux

- meuleuse à manivelle

- boules de chrome pour broyeurs à billes

- distributeur de broyage

- pavés calcaires en pavés de pierre