Iron ore beneficiation: an overview - ScienceDirect

2023.1.1 The beneficiation methodology includes processes that improve the physical, chemical, and metallurgical characteristics of iron ore concentrate that makes it desirable for iron-making processes. Such methods include size reduction or

consulter en ligne

Beneficiation of Iron Ore - 911 Metallurgist

2016.5.24 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard

consulter en ligne

(PDF) An overview of the beneficiation of iron ores via

2014.3.1 Abstract Flotation is the most effective solution, both technologically and economically, when upgrading iron concentrates.

consulter en ligne

Existing and New Processes for Beneficiation of Indian

2020.2.8 3 Different Methods of Iron Ore Beneficiation 3.1 Technological Developments. It is often observed that many low-grade

consulter en ligne

Beneficiation - Wikipedia

In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product (ore concentrate) and a waste stream (tailings). There are many different types of beneficiation, with each step furthering the concentration of the original ore.

consulter en ligne

Ore Beneficiation - an overview ScienceDirect Topics

Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion.

consulter en ligne

Treatment of iron ore beneficiation plant process water by ...

2021.1.1 Treatment of iron ore beneficiation plant process water by electrocoagulation Add to Mendeley Process water collected from the iron ore

consulter en ligne

Characterization and Beneficiation of Dry Iron Ore Processing Plant ...

2018.9.18 Characterization and beneficiation of dry iron ore processing plant reject fines of Khondbond region, India, was investigated. Different characterization techniques

consulter en ligne

A Study on High-Grade Iron ore Beneficiation to Reduce ... - Springer

2020.5.21 The study here highlights the optimization of beneficiation circuit for high-grade iron ore to attain higher productivity of both Pellet Plant and Blast Furnace with

consulter en ligne

Iron ore Beneficiation Plant - FTM Machinery

What is iron ore beneficiation plant? According to different physical and chemical properties of the ore, using the gravity method, flotation method, and magnetic separation method to separate useful minerals from

consulter en ligne

SGS MINERALS SERVICES – T3 SGS 960 11-2009

BENEFICIATION SGS MINERALS SERVICES’ EXPERTISE WITH BENEFICIATION Beneficiation is the process where ore is reduced in size and gange separated from the ore. Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit. Separation of certain minerals can be efficiently achieved by

consulter en ligne

Beneficiation Plants and Pelletizing Plants for Utilizing Low

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept.,

consulter en ligne

Iron Ore Beneficiation Plant - JXSC Machinery

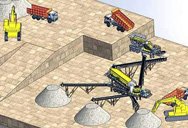

Iron ore beneficiation is mainly a process of separating valuable minerals and iron minerals from ores to extract high-quality iron ore. The iron ore process mainly includes crushing, grinding, washing, beneficiation,

consulter en ligne

Treatment of iron ore beneficiation plant process water by ...

2021.1.1 Iron ore process water obtained from the beneficiation plant was treated using EC process. Impact of various operating conditions like most effective pair of the electrode, electrode configuration, current density (j), inter-electrode distance (i d ), and solution conductivity (S) on metal ions removal as well as various water quality

consulter en ligne

Beneficiation - an overview ScienceDirect Topics

The beneficiation process begins with milling, which is followed by flotation for further beneficiation. At the first stage, extracted ores undergo the milling operation to produce uniformly sized particles for crushing, grinding, wet or dry concentration. The type of milling operable in a certain plant is chosen by capital investment and ...

consulter en ligne

Process flow diagram of Chadormalu Iron ore concentrator plant.

For iron ores with significant amounts of rare-earths [47,[320][321][322][323] [324] [325], the incorporation of rare-earth recovery steps can improve the economy of the ore beneficiation process ...

consulter en ligne

Solar-thermal beneficiation of iron ore: System-level dynamic ...

2022.12.11 This study present the system-level dynamic performance and techno-economic optimisation of solar-thermal beneficiation of iron ore. Fig. 1 illustrates the schematic diagram of the dynamic model for the proposed solar-thermal beneficiation plant. The whole process is composed of the following units: the air-based PTC, the

consulter en ligne

Beneficiation: Quality Starts with the Ore — Metals Magazine

2017.2.1 In general, iron ore beneficiation is done at the mining site. The concentrated iron ore is subsequently sintered or pelletized, depending on the grain size distribution, before it is charged to an ironmaking plant. In cases where after the initial processing steps the iron ore fractions are of inferior quality (too fine or low iron content ...

consulter en ligne

How to Extract Iron from Hematite: Methods and Plants

2023.2.15 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm. This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting.

consulter en ligne

(PDF) Iron Ore Pelletizing Process: An Overview - ResearchGate

2018.7.11 Iron ore fines generated from the beneficiation process cannot be used directly in blast furnaces for steel making. So these fines are converted into sized spherical balls, known as iron ore ...

consulter en ligne

M/s Star Minerals Proposed Iron Ore/ Mn Ore Beneficiation Plant

Karnataka is having abundant quantity of iron ore fines, which almost contribute to 60-70% of the total iron ore reserves of the state. The good quality iron ore (more than 63% Fe Content) is being mined, for the past 15-20 years and the availability of this, is becoming scarce. To make effective utilization of the lower grade iron ores (i.e. with

consulter en ligne

22.4: Beneficiation - Chemistry LibreTexts

22.4: Beneficiation. Beneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream. Beneficiation may involve physical or chemical processes. Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue.

consulter en ligne

The Port Hedland FINMET (R) Project - ResearchGate

1997.9.15 ore fines in the beneficiation plant. Iron ore fines . containing 62-63% to tal Fe ... The Finmet process is a fluidized iron ore reduction process which uses fine ores as a feedstock.

consulter en ligne

Novel Technology for Comprehensive Utilization of Low-Grade Iron Ore

2022.4.18 In this study, a novel technology for the comprehensive utilization of low-grade iron ore is presented. For the iron ore with a Fe content of 24.91%, a pilot-scale study of pre-concentration, suspension magnetization roasting, grinding, and low-intensity magnetic separation was conducted, and an iron concentrate with a grade of 62.21%

consulter en ligne

Enhanced Iron Recovery from Ultrafine Iron Ore Tailing Through

2022.5.18 The overall concentrate obtained from the developed beneficiation process of iron ore tailing has 61.53% Fe, 5.27% SiO2, and 2.44% Al2O3 with 26.34% weight recovery. And final tailing obtained from the entire process has 36.98% Fe with 73.66% weight which cannot be upgraded using the conventional beneficiation process.

consulter en ligne

Simec Mining 950tph Iron Ore Beneficiation Wash Plant - CDE

950tph iron ore beneficiation wet processing project in South ... The iron ore wash plant also removes clays from the feed material and the combined effect means the Fe content increases from between 43.4% and 52 ... A1500 AquaCycle™ thickeners are deployed across the two plants to form a concentrated tailings sludge and recycle process water.

consulter en ligne

Beneficiation (Metallurgy) - an overview ScienceDirect Topics

Jigging is a widely used mineral beneficiation process, despite being one of the oldest forms of mineral separation. Usage also extends to industries such as plastics recycling (Ito et al., 2010). Jigging is especially useful for low-grade iron ores, potentially creating saleable product from what would otherwise be mine waste.

consulter en ligne

Modeling and Optimisation of Spiral Concentrator for Beneficiation

2020.7.23 Sadeghi M, Bazin C, Renaud M (2014) Effect of wash water on the mineral size recovery curves in a spiral concentrator used for iron ore processing. Int J Miner Process 129:22–26. Article Google Scholar Santanu Sarkar and Supriya Sarkar (2018) Beneficiation of rejects slime of iron ore by means of sequential leaching.

consulter en ligne

BENEFICIATION在剑桥英语词典中的解释及翻译

BENEFICIATION的意思、解释及翻译:1. the process of treating ore (= rock from which metal can be obtained) or similar material from。。

consulter en ligne

BENEFICIATION OF IRON ORE - National Institute of Technology,

Appropriate beneficiation process has to be advanced to reduce the waste generation in mines and for the sustainable ... 2.4 Slimes of Iron ore 11 3. BENEFICIATION PLANT STUDY OF NOAMUNDI IRON ORE MINE 14 3.1 Mineral Processing 15 3.2 Primary ...

consulter en ligne

>> Next:Charbon Végétal Bail De Concassage

- faible capacite portable broyeur de pierres en inde

- diagramme de processus ferromagnes

- calcaire broyeur à boulets de broyage en zambie

- Details De Concassage Pierre

- rapport de projet sur les métaux bleus et le concassage

- materiel de chantier

- Tonnes Powl De La Centrale Moulin Capacité De Balle De

- animation de la machine concasseur

- imprime bleu de minerai de fer concasseur

- quel est le meilleur concasseur broyeur chine

- broyage chargeur de balle dans lusine de ciment

- vertical concasseur pl

- usine de machine concasseur en belgique

- lame de rechange broyeur alko dynamic micro

- tours de pierres précieuses