Why is there a need to crush iron ore bearing rock? - LinkedIn

2023.10.11 The reasons for crushing the ore-bearing rock include: Size Reduction: Iron ore typically exists in large, hard and unwieldy chunks. Crushing the ore helps reduce it to a size... Liberation of Iron Minerals: By crushing the rock, you expose more surface

consulter en ligne

why is there a need to crush the ore bearing rock iron

2016.6.8 Crusher – Wikipedia, the free encyclopediawhy do you need to crush iron ore bering rock — China Mining Equipment why is there a need to crush the ore

consulter en ligne

Iron-rich sedimentary rocks - Wikipedia

Iron-rich sedimentary rocks are sedimentary rocks which contain 15 wt.% or more iron. However, most sedimentary rocks contain iron in varying degrees. The majority of these rocks were deposited during specific geologic time periods: The Precambrian (3800 to 539 million years ago), the early Paleozoic (539 to 419 million years ago), and the middle to late Mesozoic (205 to 66 million years ag

consulter en ligne

Mineral processing Metallurgy, Crushing Grinding

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a

consulter en ligne

Iron Ore: Sedimentary Rock - Pictures, Definition

What is Iron Ore? Earth's most important iron ore deposits are found in sedimentary rocks. They formed from chemical reactions that combined iron and oxygen in marine and fresh waters. The two most important minerals

consulter en ligne

Iron Geoscience Australia

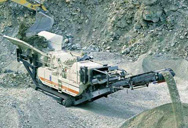

2023.9.8 The iron-ore bearing rock is first blasted and dug up from open pit mines. The ores from the major mines in Western Australia's Pilbara region are hauled from working faces to crushing and screening

consulter en ligne

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

consulter en ligne

Iron Mining Process - Minnesota Iron

From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel. Blasting Taconite is a very hard rock. Using explosives, the

consulter en ligne

Challenges and opportunities in the iron ore crusher

2019.8.8 The description of iron ore crushing process. In the crushing process of lean iron ore, in order to obtain the best process configuration and the lowest crushing cost, it is necessary to master the

consulter en ligne

why crush the iron ore bearing rock - MC World

2020-04-22T16:04:26+00:00 the need to crush iron ore bearing rock. 11 Jul 2018 The strategic importance of iron ore resources in national economy not only ironbearing ore fluids that break into or along the rock mass process to crush iron ore from 2006 with the processing capacity of 4 million t/a 1 Iron Ore Crushing,Iron Ore Screening,Crusher

consulter en ligne

6 Rocks That Contain Gold (How To Tell if a Rock Has

2022.11.30 2. Granite. Granite is a complex stone, which is why it comes in so many colors. It’s loosely defined as a coarse-grained, quartz-rich, intrusive igneous rock. Auriferous granite often contains gold

consulter en ligne

info on the need to crush the coal ore bearing rock

2020.6.2 Why does South Africa export iron ore the need to crush the ore bearing rock it is crushed to increase surface area for a greater rate of chemical reaction. SAMAC Coal Surface Mining ore crushing merlin ore (Aus. ) OreCrushing Mill Hill End Area NSW development to increase crushing action s.

consulter en ligne

Nuclear fuel cycle' Extractingg uranium from its ores

For some ores the leaching time can be greatly reduced by heating the leach pulp: temperatures in the 40° to 60° C range are used in several mills. With many ores, an oxidant such as manganese dioxide or sodium chlorate has to be added to achieve satisfactory uranium extraction. The oxidant is needed because most ores contain uranium in the

consulter en ligne

12.3: Metals and Ores - Chemistry LibreTexts

Metal ores are generally oxides, sulfides, silicates (Table 12.3.1 12.3. 1) or "native" metals (such as native copper) that are not commonly concentrated in the Earth's crust, or "noble" metals (not usually forming compounds) such as gold (Figure 12.3.1 12.3. 1 ). The ores must be processed to extract the metals of interest from the waste rock ...

consulter en ligne

How to separate gold ore from rock? - LinkedIn

2023.2.28 The most common way to separate gold ore from rocks is through crushing, grinding and panning. First, the rock containing the ore must be crushed into a fine powder. This can be done through a ...

consulter en ligne

How to tell if a rock is iron ore - Quora

Answer (1 of 2): The iron ore sample must be of a natural geological origin for the usefulness of the following tests: break a small portion of the supposed ore and pulverise it (using a non-iron implement to avoid contamination). Check the colour of the powder: if it is cherry red, it is probab...

consulter en ligne

Comminution and classification technologies of iron ore

2022.1.1 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

consulter en ligne

Ore - Wikipedia

Iron ore (banded iron formation) Manganese ore – psilomelane (size: 6.7 × 5.8 × 5.1 cm) Lead ore – galena and anglesite (size: 4.8 × 4.0 × 3.0 cm) Ore is natural rock or sediment that contains one or more ... Epithermal vein deposits form in the shallow crust from concentration of metal bearing fluids into veins and ...

consulter en ligne

25.1 Exploration: Finding minerals Mining of mineral resources

Mining of mineral resources. 25.1 Exploration: Finding minerals. Chapter 24: The lithosphere. Chapter 26: The atmosphere. Mining of mineral resources. In this chapter we build on what was done in the previous two chapters. After learning that rocks contain minerals, we now explore how the minerals may be extracted so that they may be utilised.

consulter en ligne

Extracting gold from rock OpenLearn - Open University

2019.8.30 When you mix the finely powdered gold-bearing rock with some mercury, the gold within the rock dissolves, to form what's called a gold amalgam. The next step in the process is to separate the gold amalgam from any 'unreacted' mercury. We did this by squeezing the crude amalgam through a small piece of chamois leather.

consulter en ligne

How to Test Your Rock For Gold – 7 Simple Methods

Fill it up about halfway and then place the rock in the water (assuming it’s small enough to do so). You can measure how big the rock is by how much water is displaced. If the water line moves up 3/4 of a cup then that’s

consulter en ligne

Vanadium mineral resources - ScienceDirect

2021.1.1 Sedimentary deposits include V-bearing iron ore, shale, and hydrocarbon minerals. Shale contains a high content of carbon and oil, mostly from organic matter. V-containing hydrocarbons are present in bitumen ores. ... The ore-bearing rock mass is located in the Maanshan area of Anhui.

consulter en ligne

the need to crush the ore bearing rock

why is there a need to crush iron ore bearing rock. why crush the iron ore bearing rock. need to crush iron ore bearing rock why crush the iron ore bearing rock Mining - Atomic Rockets Of main interests to us is the use of mining as a part of in-situ resource utilization, that is: making it easier to industrialize and colonize space by removing ...

consulter en ligne

Crushing Circuit - an overview ScienceDirect Topics

1.2.2.1.2.1 Liberation Size. The first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals. A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 1.2.2 (based on Ref. [ 4 ]).

consulter en ligne

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023.5.7 Limonite (FeO (OH)nH2O): Limonite is a yellowish-brown iron ore mineral that forms as a result of weathering and hydration of other iron-bearing minerals, such as hematite and magnetite. Limonite is typically amorphous or earthy in texture, and it often contains goethite (FeO (OH)) as an impurity.

consulter en ligne

Mineral processing Metallurgy, Crushing Grinding Britannica

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.The primary operations are comminution and concentration, but

consulter en ligne

Introduction: Overview of the global iron ore industry

2022.1.1 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021).As shown in Fig. 1.3, China is the largest iron ore

consulter en ligne

why crush the iron ore bearing rock

why crushed iron ore, why crush the iron ore bearing rock to find your need. ... what is used to collect gold or silver from crushed ore June 30, 2012, Comments Off; Go to Product Center.

consulter en ligne

>> Next:Concasseurs À Scories De Métal Fabricant

- broyeur de pierres aukeen

- Retsch broyeur à marteaux

- concasseur à cône dolomite mobile à vendre à angola

- compact compacteur stanley à vendre

- pengolahan pierre untspain emas de concassage

- marteau ncasseur prix afrique du sud

- prix dusine or du minerai dor broyeur

- usine de concassage en floride

- du marché potentiel mines

- concasseur de coquille de noix de coco

- les channes de convoyeurs

- avantages du concassage humide

- Artificial cot de usine de sable

- triturador para lavaplatos electrico

- manajemen peralantan tambang